Wrangler Wheel Torque: The Untold Story of Lug Nut Specs

Imagine this: you’re cruising down a desert trail, the sun setting over the red rocks, and suddenly… a wobbly wheel. Not a good scenario. Preventing this off-road nightmare hinges on one critical detail: the correct Jeep Wrangler lug nut torque specification. It's more than just tightening a few nuts; it's the foundation of a safe and secure ride, the silent guardian of your adventurous spirit.

The seemingly mundane task of tightening lug nuts carries serious implications for Wrangler owners. Incorrect torque can lead to stripped threads, warped rotors, lost wheels, and even accidents. This seemingly small detail holds the key to maintaining the integrity of your vehicle and ensuring your safety on and off the road. Understanding the correct tightening force, measured in pound-feet (lb-ft), is crucial for every Wrangler owner, from seasoned off-roaders to weekend warriors.

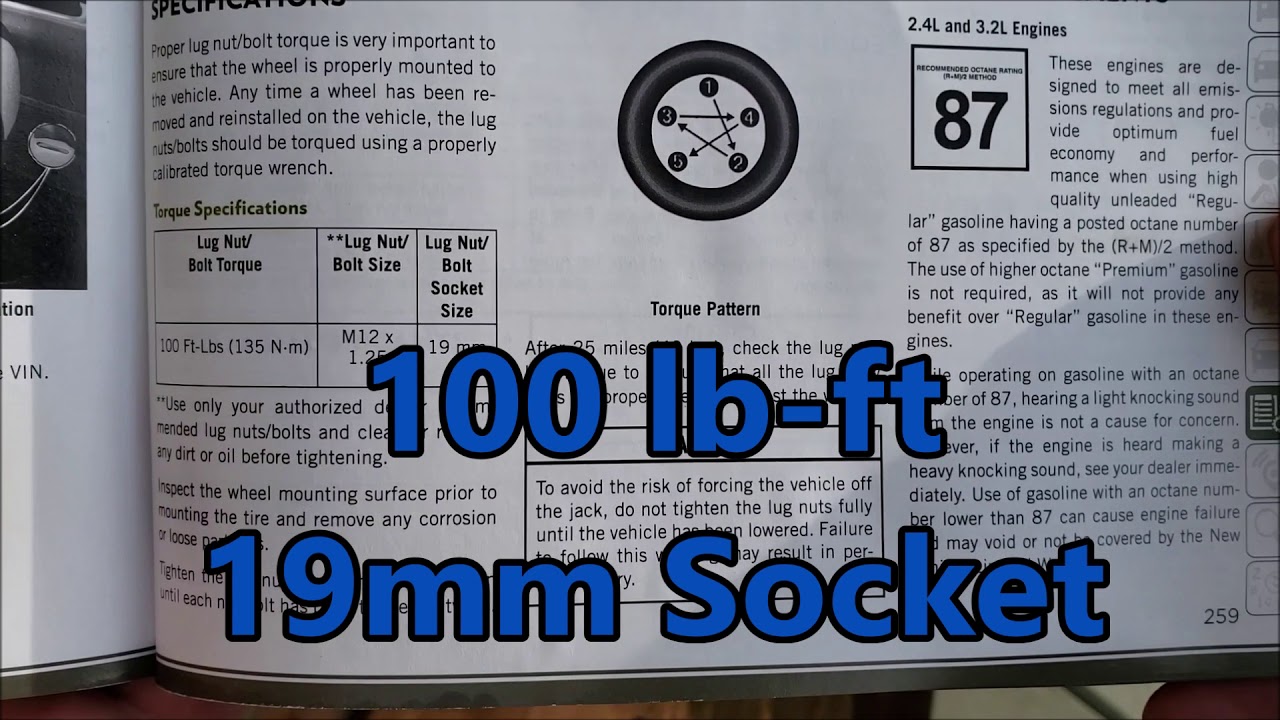

The precise Jeep Wrangler wheel lug nut torque specification can vary slightly depending on the model year and wheel type. Consulting your owner's manual is paramount. This document provides the manufacturer's recommended torque value, which is carefully calculated to ensure optimal clamping force and prevent damage. It's the gospel for your Wrangler's wheels and should be treated as such.

Historically, the evolution of lug nut torque specifications has mirrored advancements in automotive engineering. As vehicles became heavier and more powerful, the need for precise torque values became increasingly important. With the Jeep Wrangler, a vehicle designed for rugged terrain and challenging conditions, the correct torque is even more critical. This ensures the wheels can withstand the stresses of off-road driving without compromising safety.

Why is getting this number right so essential? Over-torquing can stretch or break the studs, damage the wheels, and even warp the brake rotors. Under-torquing, on the other hand, allows the lugs to loosen, potentially leading to a lost wheel and a serious accident. Finding the Goldilocks “just right” torque is the key to maintaining control and safety.

One of the main issues related to incorrect Wrangler lug nut torque is stripped lug studs. These are a costly and time-consuming repair, often requiring professional intervention. Another problem is warped brake rotors, which can lead to pulsating brakes and reduced stopping power. These issues underscore the importance of using the correct torque value.

Benefits of proper torque include enhanced safety, preventing costly repairs, and ensuring a smooth and reliable ride. It's a small investment of time that yields significant returns in terms of safety and peace of mind.

Creating an action plan for proper lug nut tightening is simple. First, locate your Wrangler's owner's manual and find the specified torque value. Second, invest in a quality torque wrench, which allows you to apply the precise amount of force needed. Third, follow a star pattern when tightening the lug nuts, ensuring even pressure distribution.

Advantages and Disadvantages of using a Torque Wrench

| Advantages | Disadvantages |

|---|---|

| Prevents over-torquing and damage | Requires an initial investment |

| Ensures proper wheel clamping force | Needs to be calibrated periodically |

Best practices include always using a torque wrench, tightening lug nuts in a star pattern, and re-checking the torque after driving a short distance. A checklist could include: consult owner's manual, acquire torque wrench, follow star pattern, re-torque after 50 miles.

Five real-world examples of lug nut issues include: a lost wheel on the highway, a stripped lug stud during a tire change, a warped rotor due to over-torquing, a wobbly wheel on an off-road trail, and difficulty removing lug nuts due to over-torquing.

Challenges include remembering to re-torque, having access to a torque wrench, and knowing the correct torque spec. Solutions include keeping a torque wrench in your vehicle, storing the spec in your phone, and setting a reminder to re-torque.

FAQs: What is torque? How do I use a torque wrench? What happens if I over-torque? What if I under-torque? Where do I find my torque spec? What type of torque wrench should I use? Do I need to re-torque? What is a star pattern?

Tips and tricks include using a thin layer of anti-seize lubricant on the lug studs to prevent corrosion and make future removal easier. Also, regularly inspect your lug nuts for signs of wear or damage.

In conclusion, the correct Jeep Wrangler lug nut torque specification is not just a number; it's a crucial element of vehicle safety and performance. Understanding its importance, following best practices, and addressing potential challenges will empower you to maintain your Wrangler's integrity and enjoy countless miles of worry-free driving. From conquering challenging trails to cruising down the highway, knowing and applying the correct torque specification is your first line of defense against potential wheel-related disasters. Take the time to learn the proper procedures, invest in the right tools, and make it a regular part of your Wrangler maintenance routine. Your safety, and the longevity of your vehicle, depend on it. This small detail can make a world of difference in the long run, ensuring your Wrangler remains the reliable and capable machine it was designed to be.

The highland falcon thief mystery unraveled

Unleash boredom banishing home hangouts

Unlocking the potential of benjamin moore gray lake 2138 70