Unlocking the Secrets of the 8-Bolt Pattern

.jpg)

In the intricate dance between form and function, where engineering precision meets aesthetic appeal, lies the humble yet crucial bolt pattern. Imagine a wheel, a seemingly simple circular object, yet its attachment to a vehicle relies on the precise arrangement of bolts, a constellation of fasteners dictating stability and safety. Among these patterns, the 8-bolt configuration stands prominent, commonly found in heavy-duty vehicles and trailers. Understanding how to decipher this pattern, to accurately measure its dimensions, is a gateway to ensuring proper fitment and optimal performance.

The seemingly simple act of measuring an 8-bolt pattern belies a deeper connection to the principles of mechanics and engineering. It's a bridge between the abstract design and the tangible reality of a vehicle's structure. But what exactly does this measurement entail? How does one navigate the intricacies of this octagonal arrangement? This exploration delves into the methods and nuances of 8-bolt pattern measurement, unveiling the secrets behind this critical aspect of vehicle maintenance and modification.

The history of bolt patterns is intertwined with the evolution of the automobile itself. As vehicles became larger and carried heavier loads, the need for more robust wheel attachments grew. The 8-bolt pattern emerged as a solution for distributing weight and stress more evenly, contributing to the safety and reliability of heavy-duty applications. Accurately determining an 8-bolt pattern is therefore not merely a technical skill; it's a continuation of this historical lineage, a testament to the ongoing refinement of automotive engineering.

The importance of accurate 8-bolt pattern measurement cannot be overstated. An incorrect measurement can lead to a mismatch between the wheel and the hub, resulting in vibrations, premature wear, and potentially dangerous driving conditions. Understanding how to properly measure this pattern is a crucial step in ensuring vehicle safety and performance. It's a practice that empowers drivers and mechanics alike, fostering a deeper understanding of the intricate workings of their vehicles.

One common issue encountered when measuring 8-bolt patterns is the confusion between diameter and bolt circle diameter (BCD). The diameter refers to the overall size of the wheel, while the BCD specifically measures the diameter of the circle formed by the centers of the bolt holes. This distinction is crucial for accurate measurement and proper wheel fitment. Another challenge lies in measuring older or corroded bolt patterns, where rust and wear can obscure the true locations of the bolt holes. Specialized tools and techniques can help overcome these challenges, ensuring precise measurements even in less-than-ideal conditions.

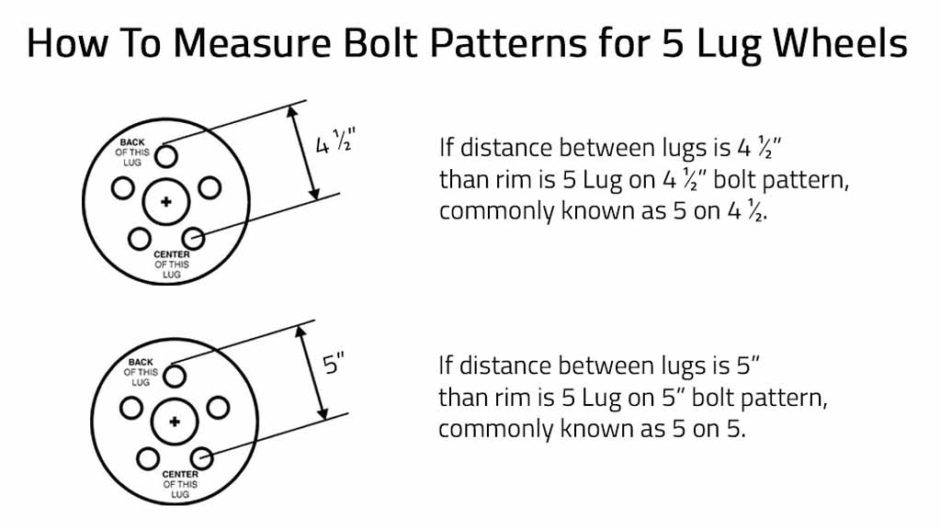

Measuring an 8-bolt pattern involves determining the bolt circle diameter (BCD). For an even number of bolts like 8, measure from the center of one bolt hole directly across to the center of the opposing bolt hole. This measurement is the BCD.

Benefits of accurately measuring an 8-bolt pattern include: 1) Ensuring proper wheel fitment and avoiding vibrations. 2) Preventing premature wear on wheel bearings and suspension components. 3) Enhancing vehicle safety by maintaining proper wheel attachment.

Step-by-step guide: 1) Locate the center of two opposing bolt holes. 2) Measure the distance between these centers. This is your BCD.

Challenges include corrosion or damage to bolt holes. Solutions involve cleaning the surface or using specialized tools for accurate measurement.

Advantages and Disadvantages of Precise 8-Bolt Pattern Measurement

FAQ: 1) What is BCD? Answer: Bolt Circle Diameter. 2) Why is measuring important? Answer: For safety and proper wheel fitment. 3) What tools are needed? Answer: A caliper or ruler.

Tip: Double-check your measurements to ensure accuracy.

In conclusion, understanding how to measure an 8-bolt pattern is a fundamental skill for anyone working with vehicles, particularly those involving heavy-duty applications. From ensuring safety on the road to preventing costly repairs, the accurate measurement of this seemingly simple pattern holds significant implications. By mastering this skill, drivers and mechanics alike contribute to the ongoing evolution of automotive maintenance, embracing precision and knowledge in the pursuit of a safer and more efficient driving experience. This understanding fosters a deeper connection between the driver and the machine, transforming a routine task into a testament to the intricacies of engineering and the pursuit of optimal performance. Take the time to measure correctly, and ensure your wheels are securely and safely attached for miles to come.

Unleash the beast dodge ram 2500 performance tuning

Unlocking creativity gacha life character posing with picsart

Unpacking the oconee county ga superior court docket