Unlocking the Secrets of Ford Stud Measurements

Within the intricate tapestry of automotive engineering, seemingly small details often hold immense significance. Consider the humble stud, a threaded fastener crucial to the structural integrity of a vehicle. For Ford vehicles, understanding the precise measurements of these studs is paramount for repairs, modifications, and ensuring overall safety. This exploration delves into the world of Ford stud measurements, unraveling their importance and practical applications.

Imagine a wheel held precariously in place by mismatched studs. The consequences could be disastrous. Accurate Ford stud measurements are fundamental to ensuring a secure connection between vital components, such as wheels, engine parts, and suspension systems. Without this precision, the structural integrity of the vehicle is compromised, potentially leading to dangerous situations.

The history of standardized stud measurements is interwoven with the evolution of the automobile itself. As cars became more complex, the need for interchangeable parts grew. This led to the development of standardized threading and measurements, enabling easier repairs and manufacturing processes. Ford, a pioneer in the automotive industry, played a significant role in establishing these standards, contributing to the development of consistent stud dimensions within their vehicle lineup.

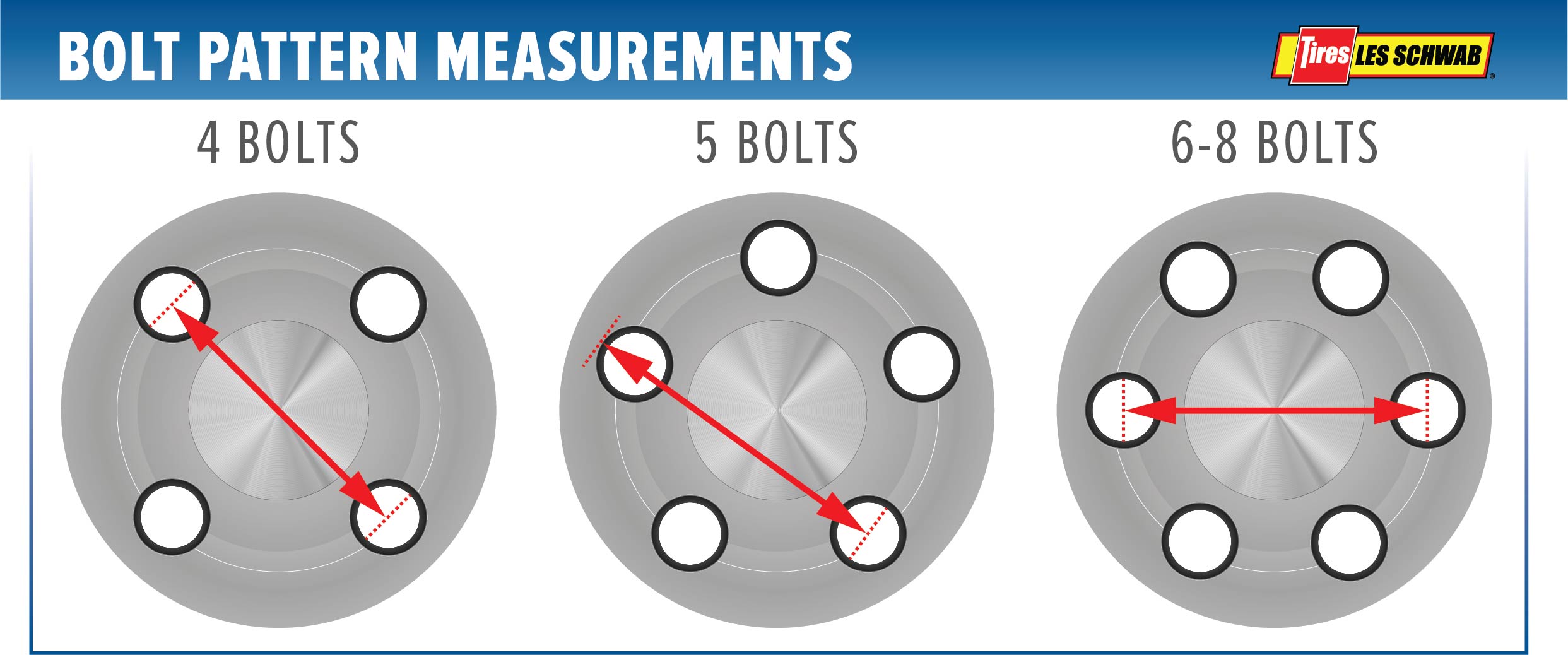

Determining the correct Ford stud measurements involves understanding two key aspects: thread pitch and bolt diameter. Thread pitch refers to the distance between threads, while bolt diameter measures the width of the stud itself. These measurements are typically expressed in millimeters or fractions of an inch. Precise measurement tools, such as calipers or thread gauges, are essential for accurate readings.

A common issue arises when attempting to replace or upgrade wheels. Different wheel designs may require specific stud patterns and lengths. Understanding the existing Ford stud measurements is crucial for selecting compatible replacements. Ignoring these details can lead to improper fitment, wheel wobble, and potential damage to the vehicle.

Understanding Ford stud patterns and their measurements allows for modifications and upgrades. Whether you are installing aftermarket wheels or customizing suspension components, knowing the correct stud dimensions is essential for a successful outcome.

Accurate stud measurements ensure safety and prevent accidents related to loose or improperly fitted components.

Proper stud sizing simplifies repairs by enabling quick and accurate replacement of worn or damaged studs.

If you are replacing wheels, always consult the vehicle's owner's manual or a trusted mechanic to determine the correct Ford stud measurements for your specific model year.

Use a caliper or thread gauge to accurately measure the thread pitch and bolt diameter of your existing studs.

It's always best practice to consult a professional mechanic if you are unsure about any aspect of working with Ford stud measurements.

Advantages and Disadvantages of Standardized Ford Stud Measurements

| Advantages | Disadvantages |

|---|---|

| Interchangeability of parts | Limited customization options in some cases |

| Simplified repairs | Potential compatibility issues with aftermarket parts |

| Enhanced safety | Requires precise measurement tools for accuracy |

Best Practices:

1. Always consult the vehicle's owner manual.

2. Use precision measuring tools.

3. Compare measurements with reputable sources.

4. Consult a professional if unsure.

5. Double-check measurements before final installation.

FAQ:

1. How do I measure thread pitch? Use a thread gauge.

2. Where can I find my Ford's stud pattern? Owner's manual.

3. What is bolt diameter? Width of the stud.

4. Can I use different studs on my Ford? Consult a mechanic.

5. Why are stud measurements important? Safety and proper fitment.

6. What tools do I need? Calipers, thread gauge.

7. Are all Ford studs the same? No, varies by model and year.

8. What if my stud is damaged? Replace it immediately.

Tips and Tricks: Keep your measuring tools clean and calibrated for accurate readings. When in doubt, consult a professional for guidance.

In conclusion, the seemingly minor detail of Ford stud measurements holds profound importance for vehicle safety, performance, and maintenance. From the historical evolution of standardized threading to the practical implications of accurate measurements, understanding these dimensions is crucial for any Ford owner. Whether you are undertaking repairs, modifications, or simply seeking to ensure the roadworthiness of your vehicle, taking the time to understand and verify Ford stud measurements empowers you to make informed decisions that prioritize safety and performance. By following best practices and consulting reliable resources, you can navigate the world of Ford stud measurements with confidence and ensure the long-term health of your vehicle. Don't underestimate the power of these small but mighty fasteners – their proper measurement is the foundation upon which a secure and reliable driving experience is built. Invest the time to understand your Ford's specific requirements and enjoy the peace of mind that comes with knowing your vehicle is securely fastened for the road ahead.

Transform your car with 3m vinyl wrap

Taylor swift and abortion rights a pop stars political voice

Unlock fun with candy heart sorting printables