The Unexpected Snag: When a Lug Nut Fails

There’s a certain quiet confidence in a well-maintained car, a subtle hum of assurance as you navigate the open road. But what happens when that quiet confidence is shattered by a sudden, jarring realization: a lug nut has broken off in the wheel. It's a scenario that can leave even the most seasoned driver feeling stranded and perplexed. This seemingly small component plays a vital role in ensuring the wheel is securely attached to the vehicle, and its failure can have significant implications.

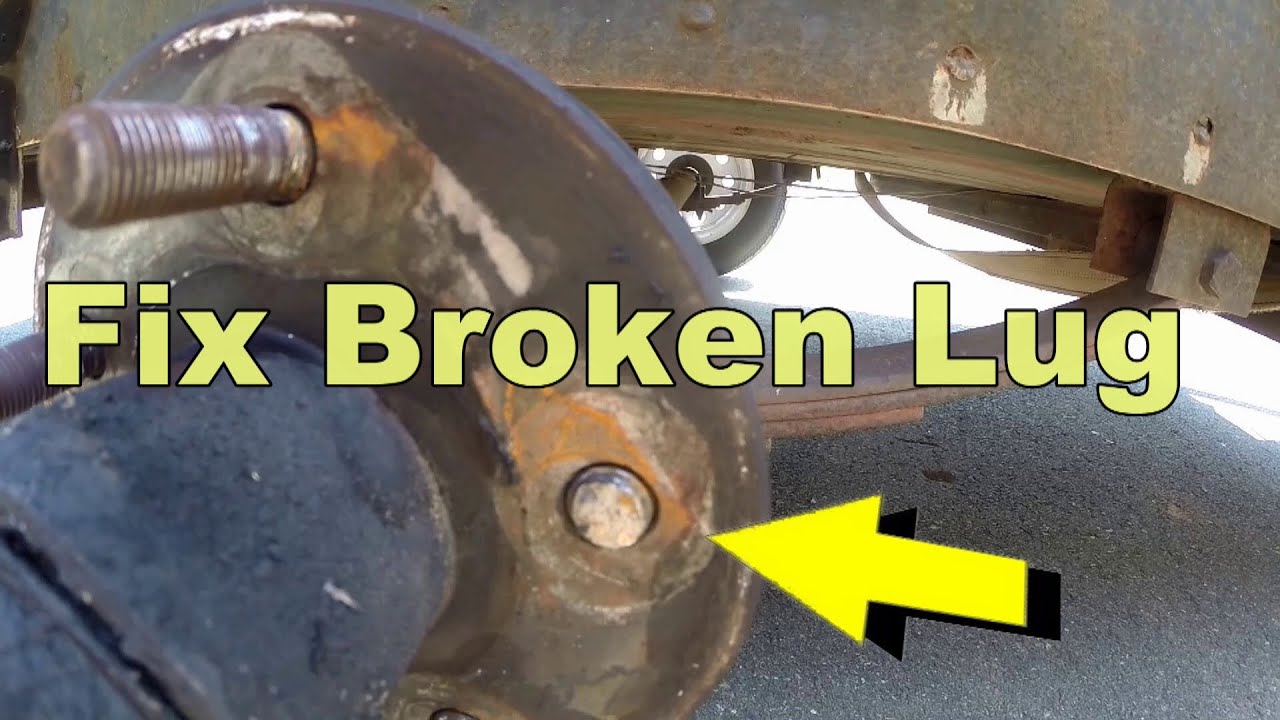

Imagine this: you’re changing a flat tire on the side of the road, only to find a stubborn lug nut refuses to budge. You apply more force, and suddenly, a sickening snap. The head of the lug nut shears off, leaving the threaded portion stubbornly lodged in the wheel. This is the frustrating reality of a broken lug nut, a surprisingly common occurrence that can quickly derail your plans. Understanding the causes, consequences, and solutions is crucial for any driver.

The primary function of a lug nut is to clamp the wheel securely against the hub, ensuring a tight and stable connection. This connection is essential for safe and controlled driving. When a lug nut breaks, this connection is compromised, potentially leading to wheel wobble, vibration, or even complete detachment. The forces exerted on the wheel during driving, including acceleration, braking, and cornering, can exacerbate the issue, making prompt action essential.

Several factors contribute to lug nut failure. Over-tightening during installation is a common culprit. Using an impact wrench without proper torque settings can easily strip the threads or shear the head of the lug nut. Corrosion, often caused by exposure to road salt and moisture, can weaken the metal, making it more susceptible to breakage. Using the incorrect size or type of lug nut can also lead to problems, as can impacting a curb or pothole, putting undue stress on the wheel and its components.

Dealing with a broken lug nut requires careful attention and the right tools. Attempting to remove the remaining portion without the proper technique can further damage the wheel stud or hub. Several methods exist for extracting a broken lug nut, including using a specialized lug nut extractor tool, welding a nut onto the broken stub, or carefully drilling it out. In some cases, the entire wheel stud may need to be replaced. Prevention, however, is always the best approach. Using a torque wrench to ensure proper tightening, regularly inspecting lug nuts for signs of corrosion or damage, and using the correct type and size of lug nut can significantly reduce the risk of this frustrating occurrence.

Extracting a broken lug nut can be challenging, even for experienced mechanics. Penetrating oil can sometimes help loosen the broken piece. If the broken part is protruding, vise grips may offer enough grip for removal. Welding a nut onto the broken stub provides a new surface to grip. If all else fails, drilling out the broken lug nut may be necessary, requiring precision and patience to avoid damaging the wheel stud.

Advantages and Disadvantages of DIY Lug Nut Removal:

Advantages and Disadvantages of DIY Lug Nut Removal

| Advantages | Disadvantages |

|---|---|

| Saves money on professional repair | Risk of damaging the wheel stud or hub |

| Can be done quickly if you have the right tools and experience | Requires specialized tools and knowledge |

Best Practices for Lug Nut Maintenance:

1. Use a torque wrench: Ensure proper tightening to avoid over-torquing or under-torquing.

2. Regular inspection: Check for signs of corrosion, damage, or looseness.

3. Correct lug nuts: Use the correct size and type specified by the vehicle manufacturer.

4. Anti-seize lubricant: Apply a small amount to the lug nut threads to prevent seizing.

5. Professional installation: Consider professional installation for new tires or wheels.

FAQ:

Q: What causes a lug nut to break? A: Over-tightening, corrosion, or impact damage.

Q: How do I remove a broken lug nut? A: Use a lug nut extractor, weld a nut, or drill it out.

Q: Can I drive with a broken lug nut? A: No, it's unsafe and can damage the wheel and hub.

Q: How do I prevent lug nuts from breaking? A: Use a torque wrench, inspect regularly, and use the correct lug nuts.

Q: What is the proper torque specification for my car? A: Consult your vehicle owner's manual.

Q: How often should I check my lug nuts? A: Every time you rotate your tires or after any impact event.

Q: What should I do if I can't remove the broken lug nut? A: Consult a professional mechanic.

Q: Are all lug nuts the same? A: No, they vary in size, thread pitch, and seat type.

In conclusion, a broken lug nut may seem like a minor inconvenience, but it can quickly escalate into a serious safety hazard. Understanding the causes, prevention methods, and solutions for dealing with a broken lug nut is essential for every driver. Regular inspection, proper tightening techniques using a torque wrench, and using the correct type of lug nut are key to preventing this issue. While DIY removal is possible, it requires specific tools and expertise. When in doubt, consulting a professional mechanic is always the safest course of action. Taking proactive steps to maintain your vehicle's lug nuts ensures a smoother, safer, and more confident driving experience, allowing you to enjoy the open road without the unexpected snag of a broken lug nut derailing your journey. Remember, a little preventative maintenance can go a long way in avoiding this common, yet potentially dangerous, automotive problem. By following the best practices outlined above, you can significantly reduce the risk of experiencing this frustrating scenario and maintain the integrity and safety of your vehicle.

Conquer your monday unleash your inner badass with motivation memes

Finding peace mental wellness in phoenix

Conquer petit jean state park your hiking trail map guide