Mastering Bolt Torque for Flange Connections

Securing a flange connection might seem like a simple task: tighten the bolts and you’re done. But beneath the surface lies a world of precision engineering where the correct bolt torque value is paramount. Applying the right amount of force, measured as torque, is the key to a secure and leak-free seal. What happens if you overtighten? What if you undertighten? The answers can have significant consequences.

Proper flange bolt tightening is essential for maintaining the integrity of various systems, from pipelines in industrial plants to the engine in your car. The correct bolt torque ensures a uniform clamping force across the flange faces, creating a tight seal that prevents leaks. This clamping force is the magic that holds everything together, resisting internal pressures and external forces. Getting it right requires understanding the specific torque requirements for your particular flange and bolt combination.

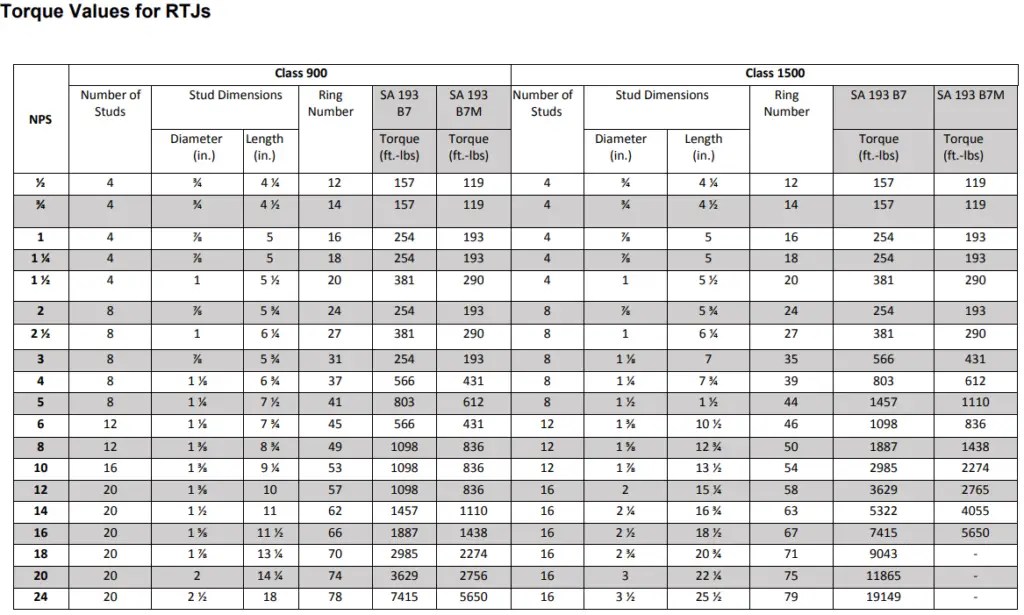

Determining the appropriate bolt torque for a flange involves several factors, including the size and material of the bolts, the flange material, the gasket type, and the operating conditions. These factors influence the necessary clamping force to achieve a reliable seal. Over-tightening can lead to bolt failure, flange damage, or gasket crushing. Under-tightening can result in leaks, vibrations, and ultimately, connection failure.

Historically, torque specifications were often determined through trial and error, leading to inconsistencies and potential problems. Today, standardized guidelines and calculations are available to determine the optimal torque values for different flange and bolt combinations. These guidelines consider the specific properties of the materials involved, ensuring a more reliable and consistent clamping force.

The significance of accurate flange bolt torque values extends beyond just preventing leaks. It also plays a crucial role in the overall safety and reliability of the system. Incorrect torque can lead to catastrophic failures, resulting in costly downtime, environmental damage, or even injury. Understanding and applying the correct torque specifications is therefore essential for maintaining a safe and efficient operation.

One common issue related to bolt torque is the variability in friction. Lubrication plays a significant role in achieving accurate torque readings. A consistent lubrication procedure is essential to minimize variations and ensure that the applied torque translates to the desired clamping force. Different lubricants have different friction coefficients, which can affect the final clamping force. Therefore, using the specified lubricant is crucial for achieving the correct bolt preload.

Benefits of correct bolt torquing for flanges include: leak prevention, improved safety, and extended service life of the components. For example, in a high-pressure steam system, correct bolt torque prevents steam leaks, which could cause burns or equipment damage. Properly torqued flanges also reduce the risk of gasket failure, minimizing maintenance and downtime.

Implementing proper bolt torque requires using calibrated torque wrenches and following the specified tightening sequence. This sequence often involves a star pattern to ensure uniform clamping force distribution across the flange. Regularly checking and re-torquing bolts, especially in critical applications, helps maintain the integrity of the connection over time.

Advantages and Disadvantages of Precise Bolt Torque

| Advantages | Disadvantages |

|---|---|

| Leak Prevention | Requires specialized tools (calibrated torque wrenches) |

| Enhanced Safety | Time-consuming if done manually for numerous bolts |

| Increased Component Lifespan | Potential for error if incorrect lubricant or tightening sequence is used |

Best practices include: using calibrated torque wrenches, following the manufacturer’s recommended torque specifications, applying lubricant consistently, and adhering to the correct tightening sequence.

Frequently Asked Questions:

1. What is bolt torque? Answer: Bolt torque is the rotational force applied to a fastener.

2. Why is flange bolt torque important? Answer: It ensures a tight, leak-free seal.

3. How do I determine the correct torque value? Answer: Consult manufacturer specifications.

4. What tools do I need? Answer: A calibrated torque wrench.

5. What is the tightening sequence? Answer: Often a star pattern, but consult manufacturer guidelines.

6. What is the role of lubrication? Answer: It reduces friction and ensures accurate torque readings.

7. How often should I check bolt torque? Answer: Depends on the application; consult manufacturer guidelines.

8. What are the consequences of incorrect torque? Answer: Leaks, damage, and potential failures.

In conclusion, understanding and applying the correct bolt torque value for flange connections is paramount for safety, reliability, and longevity of any system. From preventing leaks to ensuring structural integrity, the seemingly simple act of tightening bolts plays a critical role. By adhering to best practices, using calibrated tools, and following manufacturer specifications, we can ensure the optimal performance and safety of flanged connections. Neglecting this crucial aspect can lead to significant problems, ranging from minor leaks to catastrophic failures. Therefore, investing time and effort in understanding and implementing correct bolt torquing procedures is essential for any application involving flange connections. Taking these steps will lead to more reliable, efficient, and safer operations.

Exploring the magic of winter in paris lyrics

Finding the perfect pre owned fly fishing gear

Unlock the magic of benjamin moore green smoke