Electrical Contactors and Relays: Unsung Heroes of Power Control

Ever wonder what keeps your air conditioner humming or your industrial machinery churning? Chances are, it's the quiet workhorses of electrical systems: contactors and relays. These seemingly simple devices play a crucial role in controlling power flow, protecting equipment, and enabling automation across countless applications.

These electromagnetic switches might not be glamorous, but they are essential. They allow us to control high-power circuits with low-power signals, making them the backbone of modern electrical infrastructure. From your home appliances to complex industrial automation systems, they’re silently managing the flow of electricity, keeping things running smoothly.

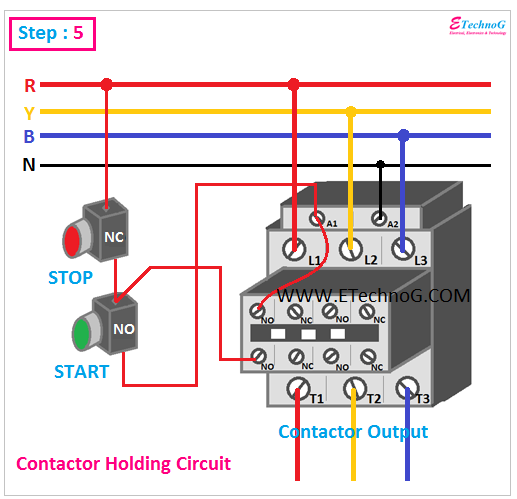

Relays, in their simplest form, are electrically operated switches. A small current flowing through a coil creates a magnetic field, which activates a switch mechanism, controlling a separate, often higher-power circuit. Contactors, on the other hand, are essentially heavy-duty relays designed to handle significantly larger electrical loads. They're the muscle behind controlling motors, pumps, and other power-hungry equipment.

The history of these devices traces back to the early days of telegraphy and the development of the electromagnetic telegraph. As electrical systems grew more complex, so did the need for reliable switching mechanisms. This led to the evolution of the relay and, later, the contactor, constantly adapting to meet the demands of emerging technologies.

One of the primary issues surrounding these switching devices is contact wear and tear. The physical act of switching electrical currents introduces arcing and erosion, which can eventually lead to malfunction. Understanding how to select the right device for the application, proper maintenance, and timely replacement are critical for preventing system failures.

Contactors are particularly important for controlling motors. They often include overload protection to prevent damage to the motor windings. Relays, while smaller, are versatile components found in numerous applications, from automotive systems to programmable logic controllers (PLCs).

Three key benefits of utilizing these components are safety, automation, and energy efficiency. By enabling remote control of high-power circuits, they minimize the risk of electrical shock. Their ability to be integrated into automated systems streamlines processes and increases productivity. Furthermore, by precisely controlling power delivery, they contribute to optimizing energy consumption.

For instance, a contactor can automatically start and stop a motor based on predefined parameters, reducing unnecessary energy usage. A relay in a lighting system can control multiple lights with a single switch, improving convenience and efficiency.

When choosing a relay or contactor, consider factors such as voltage, current rating, coil voltage, and contact configuration. Ensure the device is compatible with the intended application and provides sufficient safety margins.

Advantages and Disadvantages of Contactors and Relays

| Feature | Advantages | Disadvantages |

|---|---|---|

| Control | Remote operation, automation | Can be susceptible to electromagnetic interference |

| Safety | Isolation of high-power circuits | Contact wear and tear requires maintenance |

| Cost | Relatively inexpensive | Larger contactors can be bulky |

Best practices include: 1) Correct sizing for the load, 2) Regular inspection for wear, 3) Proper wiring and grounding, 4) Using appropriate enclosures for environmental protection, and 5) Implementing surge suppression to protect against voltage spikes.

Real-world examples include: motor starters in industrial machinery, HVAC systems, lighting control systems, automotive ignition systems, and safety interlocks in industrial automation.

Common challenges include contact sticking, coil burnout, and contact erosion. Solutions involve proper maintenance, ensuring adequate ventilation, and using surge protection devices.

FAQ: 1) What's the difference between a relay and a contactor? 2) How do I select the correct size relay? 3) What causes contact sticking? 4) How often should I inspect my contactors? 5) What are the signs of a failing relay? 6) How do I troubleshoot a contactor circuit? 7) What safety precautions should I take when working with contactors? 8) What are the different types of relays available?

Tips include using a multimeter to check coil continuity and contact resistance, and consulting manufacturer datasheets for specific recommendations.

In conclusion, electrical contactors and relays are the unsung heroes of power control, quietly ensuring the smooth operation of countless electrical systems. From basic household appliances to complex industrial machinery, their role is indispensable. Understanding their function, benefits, and proper implementation is crucial for anyone working with electrical systems. These seemingly simple devices offer sophisticated control, enhanced safety, and improved energy efficiency. By following best practices and addressing potential challenges proactively, you can ensure the reliable and long-lasting performance of these essential components. Investing time in understanding these fundamental components is an investment in the efficiency, safety, and reliability of your electrical systems. Explore resources like manufacturer datasheets and industry publications to deepen your understanding of contactors and relays. Your electrical systems will thank you.

Finding the perfect iron works near you

Breathing life into scripture the power of biblical engagement

Unlocking deep sound exploring the 10 inch wet sounds amplifier