Decoding the Compressor Start Relay: Your Guide to Wiring and Troubleshooting

Ever wondered about the magic behind your refrigerator or air conditioner humming to life? It's not magic, it's the compressor start relay, a small but mighty component responsible for kickstarting these essential appliances. Understanding the compressor start relay wiring schematic is crucial for troubleshooting and maintaining these systems. This comprehensive guide will delve into the intricacies of the compressor motor start relay wiring, providing you with the knowledge you need to keep things running smoothly.

The compressor is the heart of any refrigeration or cooling system. However, it requires a substantial initial jolt of power to overcome inertia and begin its cycle. This is where the start relay steps in. Imagine trying to push a heavy cart – the initial push requires more effort than keeping it rolling. The start relay provides that initial "push" to the compressor motor, ensuring a smooth start-up.

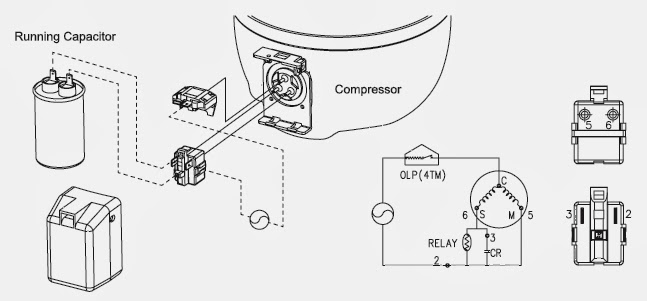

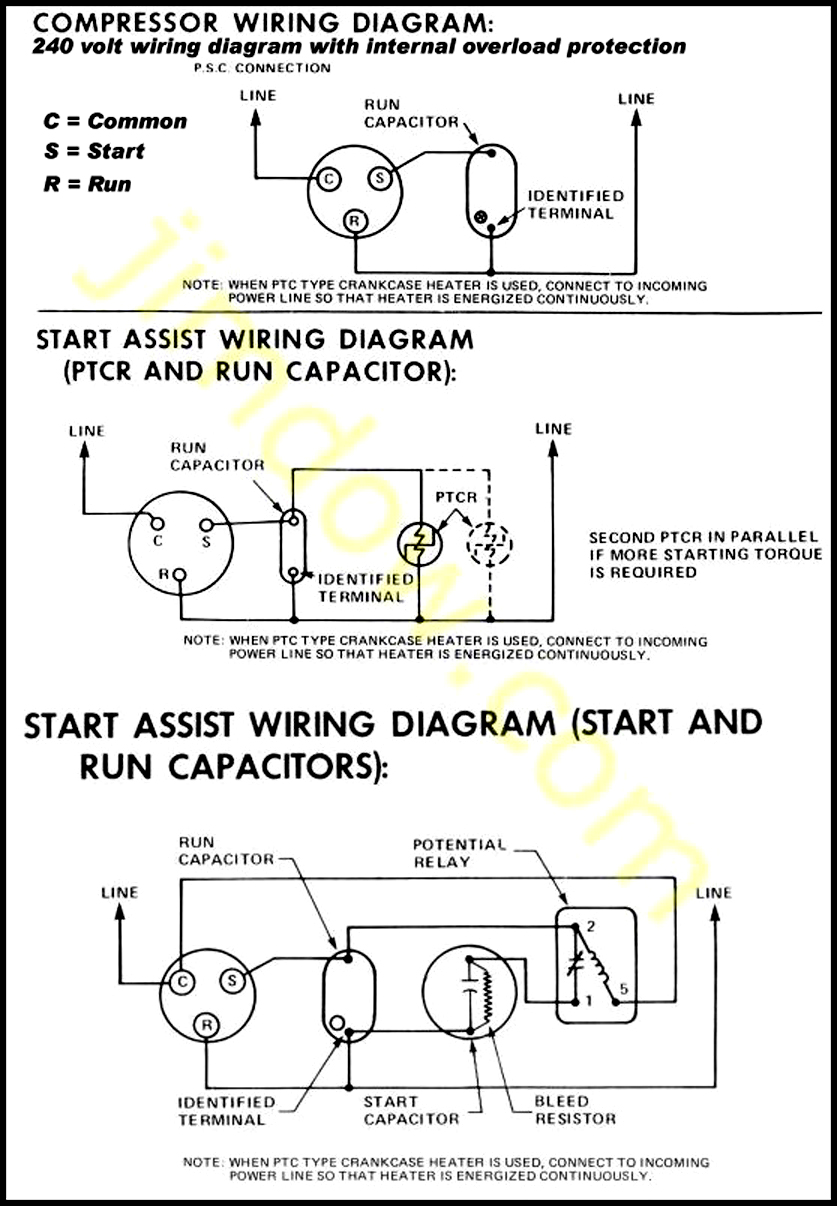

The wiring configuration for a compressor start relay is relatively straightforward, but crucial to get right. An incorrect connection can lead to malfunction or even damage to the compressor. The relay typically involves connections to the main power supply, the compressor's run winding, and the start winding. Understanding this starting relay circuit diagram is the key to diagnosing and fixing common issues.

The history of the compressor start relay is intertwined with the development of refrigeration and air conditioning technology. As these systems became more complex and widespread, the need for a reliable starting mechanism became paramount. The start relay emerged as an efficient and cost-effective solution, allowing for the seamless operation of these essential appliances.

The importance of a correctly wired compressor relay cannot be overstated. A faulty relay can lead to a range of problems, from inefficient cooling to complete compressor failure. Common issues include a humming compressor that fails to start, overheating, and premature wear and tear. By understanding the compressor start relay wiring diagram, you can effectively troubleshoot these issues and prevent costly repairs.

The start relay utilizes a potential relay switch and a start capacitor. The start capacitor provides a temporary surge of power to the start winding of the compressor motor. Once the motor reaches a certain speed, the potential relay switch disengages the start capacitor and the motor continues running on the run winding.

One benefit of using a start relay is increased efficiency. By providing the necessary starting boost, the compressor avoids drawing excessive current during start-up, reducing energy consumption.

Another advantage is prolonged compressor lifespan. The start relay prevents the motor from overheating during the initial starting phase, extending its operational life.

Finally, the start relay contributes to quieter operation. A smooth start-up minimizes noise and vibration, resulting in a quieter appliance.

Troubleshooting a compressor start relay involves checking the relay switch, the start capacitor, and the wiring connections. A multimeter can be used to test the continuity of the relay and the capacitance of the capacitor.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Increased Efficiency | Potential Relay Failure |

| Prolonged Compressor Lifespan | Capacitor Degradation |

| Quieter Operation | Wiring Issues |

Best Practices:

1. Always disconnect power before working on any electrical components.

2. Use a wiring diagram specific to your compressor model.

3. Secure all wiring connections properly.

4. Use appropriate wire gauge for the current draw.

5. Regularly inspect the relay and capacitor for signs of wear and tear.

FAQs:

1. What does a compressor start relay do? It provides a temporary power boost to start the compressor motor.

2. How do I test a start relay? Use a multimeter to test the relay switch and capacitor.

3. What are the signs of a faulty start relay? Humming compressor, overheating, or failure to start.

4. Can I replace a start relay myself? Yes, with proper precautions and following a wiring diagram.

5. What causes a start relay to fail? Age, wear and tear, or electrical surges.

6. Where can I find a compressor start relay wiring diagram? Consult your appliance's manual or search online for specific models.

7. What type of capacitor is used in a start relay? Typically, an electrolytic capacitor.

8. How do I choose the right start relay for my compressor? Match the relay specifications to your compressor's requirements.

In conclusion, the compressor start relay is a critical component in refrigeration and cooling systems. Understanding its wiring diagram, function, and troubleshooting techniques is essential for maintaining the efficiency and longevity of these appliances. By following best practices and addressing issues promptly, you can ensure optimal performance and avoid costly repairs. Investing time in understanding the compressor start relay wiring schematic empowers you to take control of your appliance's maintenance, ensuring a comfortable and efficient environment for years to come. This knowledge not only saves you money but also contributes to the sustainable use of these vital appliances. Don't underestimate the power of this small but mighty component – mastering its intricacies can make all the difference in keeping your cool.

Scoring big your guide to play it again sports in ann arbor michigan

Experience kuala sungai baru melaka your homestay awaits

Dominate your league unlocking fantasy football defense rankings